Lihlahisoa

Mochini oa Automatic Tufting le Trimming o nang le All-in-one

Kopo e ka Sehloohong

Mochine o loketse mefuta eohle ea borashe, joalo ka: borashe ba meno, borashe ba litlolo, borashe ba indasteri le borashe bo bong.E ne e sebelisoa bakeng sa likhoele tsa borashe tse hlokahalang bakeng sa mefuta e fapaneng ea borashe.

Karolo e ka Sehloohong

● Mochine o sebelisoa ka li-bearings tse sa tšoaneng tse tsoang linaheng tse ling tse tsoang Jeremane IMA, AFG, DURBAL le Japane NSK, IKO, e le hore boleng ba thepa bo tiisetsoe.

● Hlahisa thekenoloji ea Jeremane ea CNC ho etsa lipatlisiso ka boikemelo le ho hlahisa mochine o bohlale oa ho laola lipalo-palo oa khomphutha ea LCD, le mochini oa Japane oa Fuji four-axis original servo motor, o etsang hore thepa e tsitse, e sebetse hantle ka makhetlo a mangata, e sebetsa hantle le e matla. bokhoni ba ho thibela ho kena lipakeng.

● Sesebelisoa sa ho sebetsana le li-feeder ka ho feletseng, sebopeho sa sebele sa bokahohle, sehokelo sa letsoho sa mochini, e le hore tlhahiso le ts'ebetso ea lisebelisoa li ka boloka litšenyehelo, 'me ho bonolo ho fetola le ho fetola mehlala.

● Sebopeho sa lithipa tse peli tsa ho khaola ka makhetlo a mabeli ka mokhoa oa ho sila o loketse ho qaptjoa le ho hlahisa libopeho tse sa tšoaneng tsa lihlahisoa.

● Mekhahlelo e robeli ea omnidirectional e ntle le e mpe ea khoune e ts'oarellang le disc e tsoang kantle ho naha ea taemane, e le hore karo-karolelano ea ho sila le ho pota-pota e fetang 90% e phahameng ho feta ea maemo a naha.

● Etsa sesebelisoa sa ho tlosa lerōle ka mokhoa o itekanetseng

● Beha sebaka sa mochini ho lokisa se hlokahalang bakeng sa liketso tsa moralo oa sehlahisoa se ikhethileng (joalo ka sehlahisoa se videong, se nang le tšebetso ea ho fepa ka boiketsetso e etselitsoeng ho boloka litšenyehelo tsa basebetsi)

Tlhaloso

| Mekhahlelo ea mantlha ea | |

| Boholo ba moamoheli: 197cmX245cmX157cm | Boholo ba Vacuum: 105cmX84cmX196cm |

| (moamoheli) Boholo ba kesi ea lehong: 200cmX250cmX190cm | (vacuuming) Boholo ba kesi ea lehong: 90cmX110cmX205cm |

| Boima ba Nete: 1180KG + 220KG | Boima ba sefapano: 1420KG + 280KG |

| Saese ea disassembly1: 131cmX244cmX157cm | Saese ea disassembly2: 108cmX133cmX157cm |

| Matla a kenang: mekhahlelo e meraro 380V 50-60HZ | Phetoho ea matla: 32A↑ |

| Matla: 7KW | Khatello ea moea e hatelitsoeng: 0.65MPa |

| Pipe e kenang: 12MM | Tšebeliso ea moea: ≥1㎡/MIN |

| Lerata: 65 (dB) |

|

| Nomoro ea Tanka: Xindejia Lubricating Oil No. CC40 | Tšebeliso ea lisebelisoa: sheba bukana ea litaelo le video ea ts'ebetso ea lisebelisoa |

Lintlha tse qaqileng

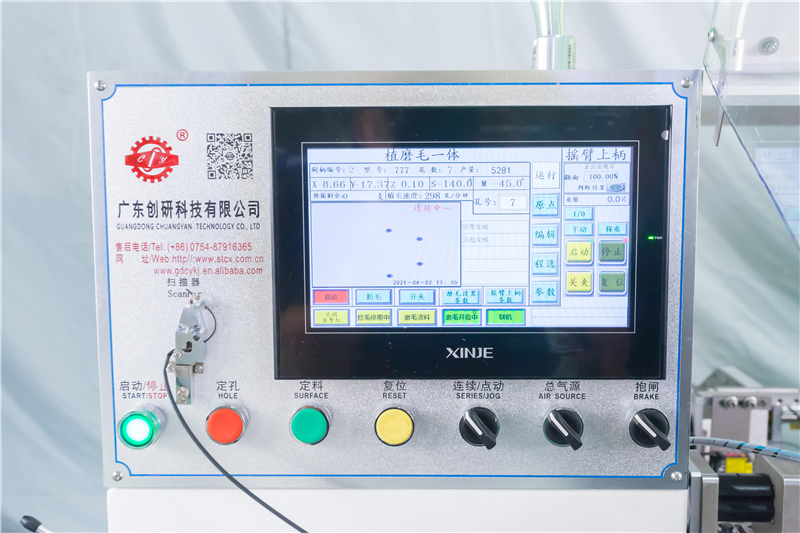

Intelligent Cnc Control Computer Part

Likarolo: 1 kenyelletso ea theknoloji ea Jeremane ea CNC ho nts'etsapele mahlale a bohlale a ho hlahloba lesoba la CNC

2. Ho sebelisa American CNC CPU chip e tsoang linaheng tse ling, P4 dual-core processor

3. Ho latela mokhoa o itekanetseng le taolo ea lebelo, boemo bo nepahetseng le ts'ebetso e bonolo

4. Sistimi e tsitsitse ebile e ka tšeptjoa, e ikamahanya le maemo a fapaneng, 'me e na le tšitiso e matla ea ho hanyetsa

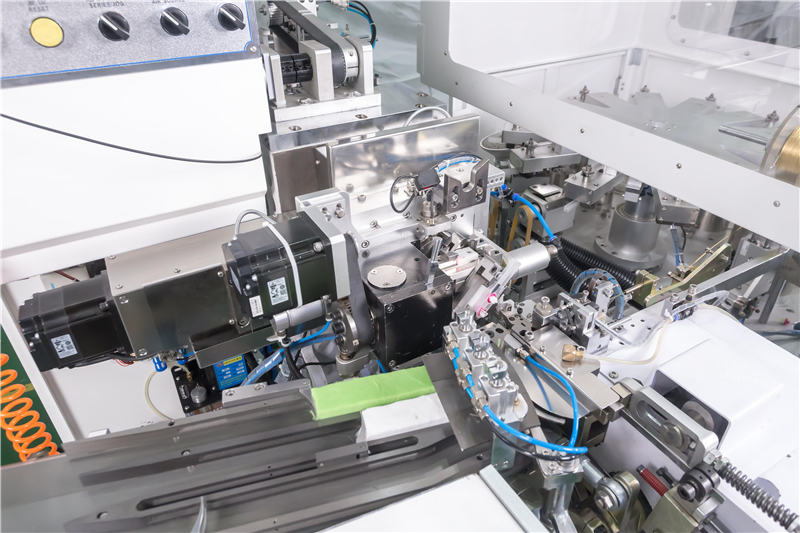

Servo Motor Karolo ea Worktable le ho sebetsana le Phetoho

Likarolo: 1. Thepa e amohela li-motor tsa servo tse nepahetseng tse tsoang kantle ho naha ho tsoa Japane

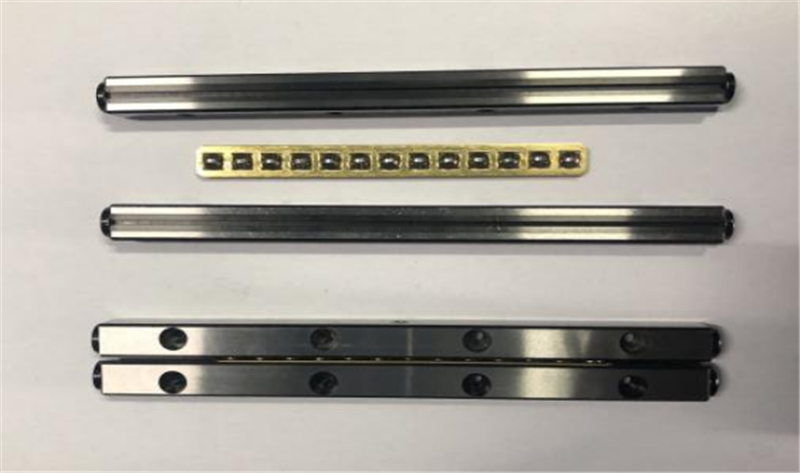

2. Adopt German imported precision C1 double threaded ball screw

3. E etselitsoe hore le ka mohla e se ke ea apara, mofuta oa seporo sa mabone a mabone a phahameng, se tiisitsoeng, li-bearings tse itšebetsang, li lokolla boima ba tafole ea X-axis, 'me li fihlelle 850-speed high-speed tufting effect.

Karolo ea Coordinate ea Auto Scanning

Likarolo: 1. Amohela borashe bo phahameng ba infrared infrared othomathiki sekenang borashe ba meno sebetsana le masoba coordinates

2. Bokhoni bo phahameng bo fetola boholo, bo bonolo ho sebetsa, bo potlakile ebile bo bonolo ho ithuta

3. Ho nepahala ho phahameng ha lihokahanyo tsa maemo: mamello ± 0.02mm

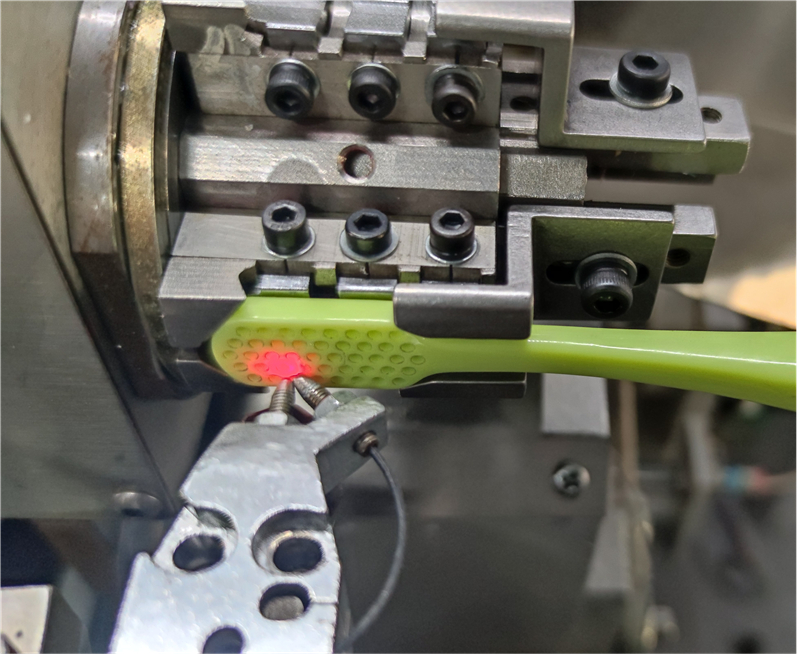

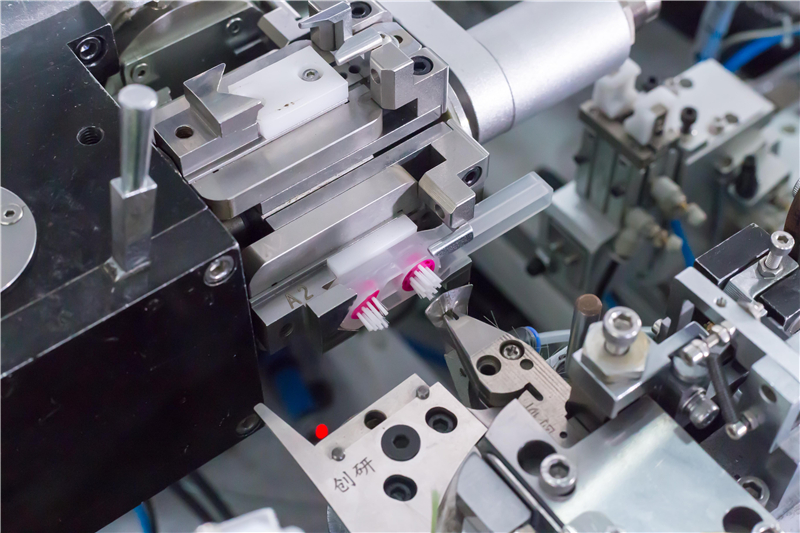

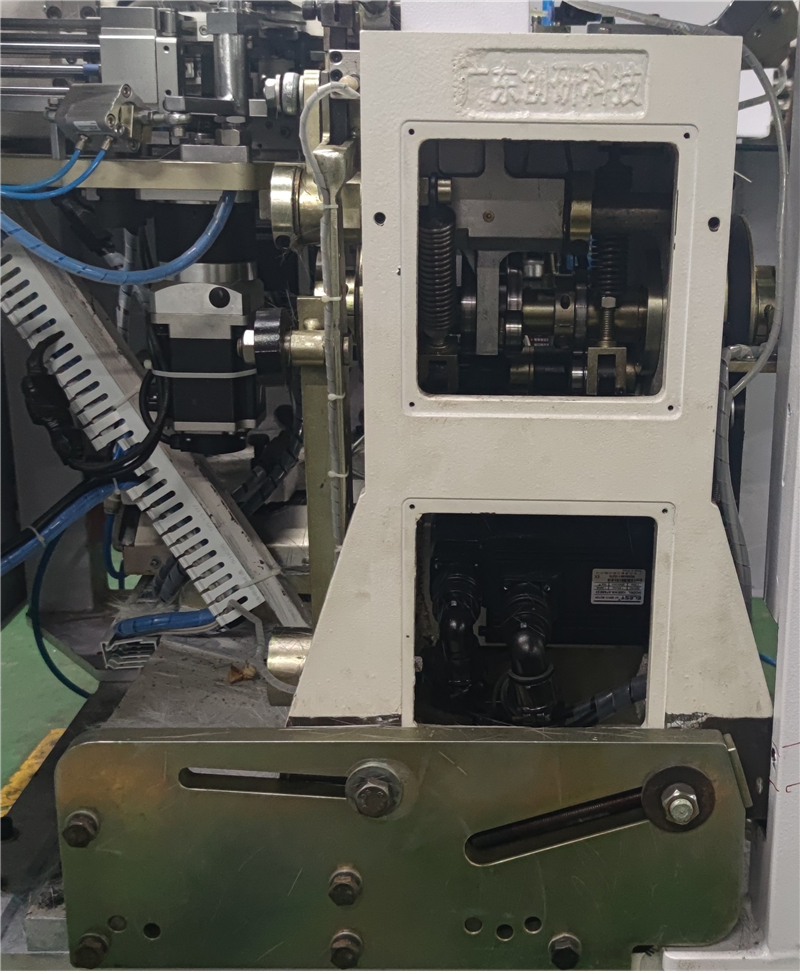

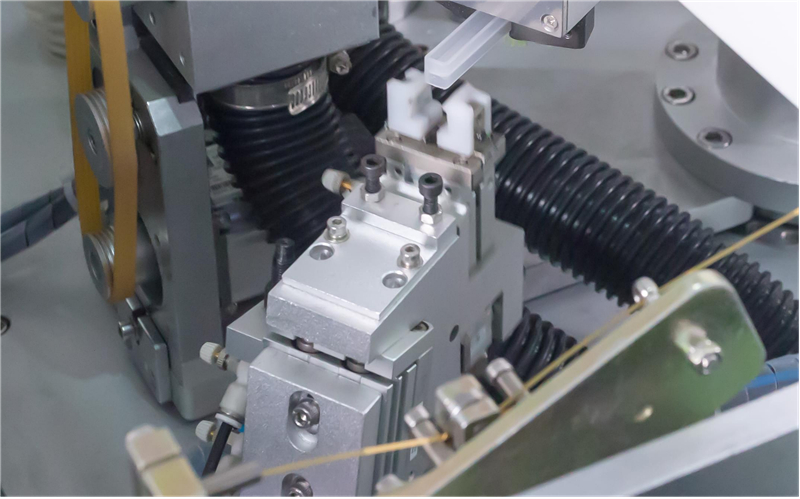

Karolo ea High Tufting

Likarolo: Adopt Germany thepa e tsoang kantle ho naha, ka theknoloji ea profeshenale le lisebelisoa tse phahameng tsa ho sebetsa ka mokhoa o nepahetseng haholo ho etsa hlooho ea tufting, thipa ea moriri, molamu oa tufting, boima bo phahameng, boima bo botle, khanyetso e matla ea ho roala, phoso ea theknoloji ea ho sebetsa ± 0.01mm, e le hore botsitso ba tufting, ts'ebetso e phahameng ea ts'ebetso. , tsitsipano e matla, eseng khoele e hlephileng

Universal Fixture

Sebopeho: Sebopeho sa bokahohleng ka kutloisiso ea 'nete,' me se ka lema mefuta eohle ea borashe ba meno ea motlakase ntle le mehatla, ntle le sehlahisoa se seng le se seng se hlophisitsoeng kapa lihlahisoa tse khethehileng li ke ke tsa hlahisoa.

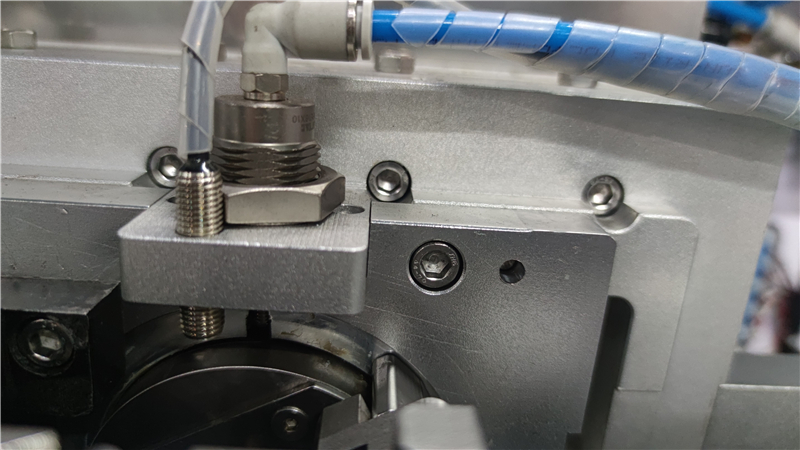

Shaft e potolohang

Sebopeho: Khokahano e nepahetseng e phahameng e potolohang ka kotloloho ea Z (ha ho hlokahale ho khutlisa lebanta)

Karolo ea Lebokose la Filament (mebala e 'meli)

Karolo ea Lebokose la Filament (mebala e meraro)

Sebopeho: 1. Ho atolosa moralo ho netefatsa botsitso ba molumo oa filament le ho eketsa tlhahiso

2. Moralo o hatelletsoeng ka makhetlo a mabeli, ho hatella filament e tsoelang pele, ho netefatsa botsitso bo phahameng ba ho khetha likhoele, ha ho na likhoele tse tšesaane, ha ho tšolloe likhoele.

3. Mokhoa o khethehileng oa ho roala tšepe oa moriri oa moriri o tiisa boleng bo botle ba sehlahisoa

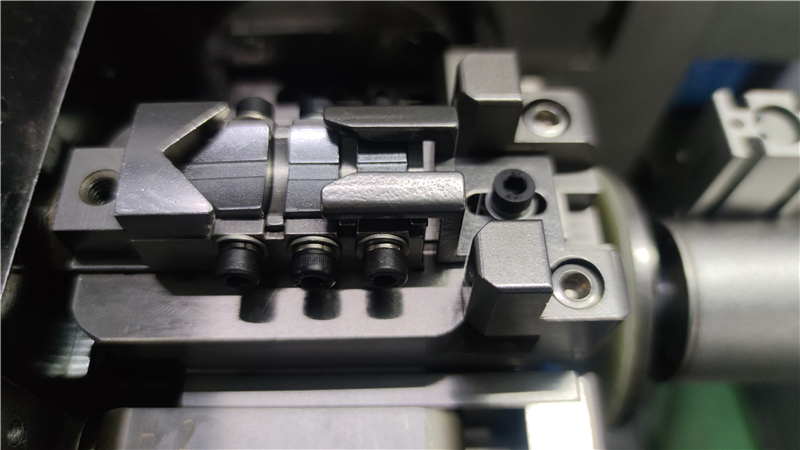

Karolo ea Square Hole

Feature: 1. E ka hlahisa borashe ba mofuta oa lisekoere, borashe bo tloaelehileng bo feto-fetoha le maemo

2.Sebopeho sa mechine se feto-fetohangmoralo, e loketseng le ho lokisa kapele.

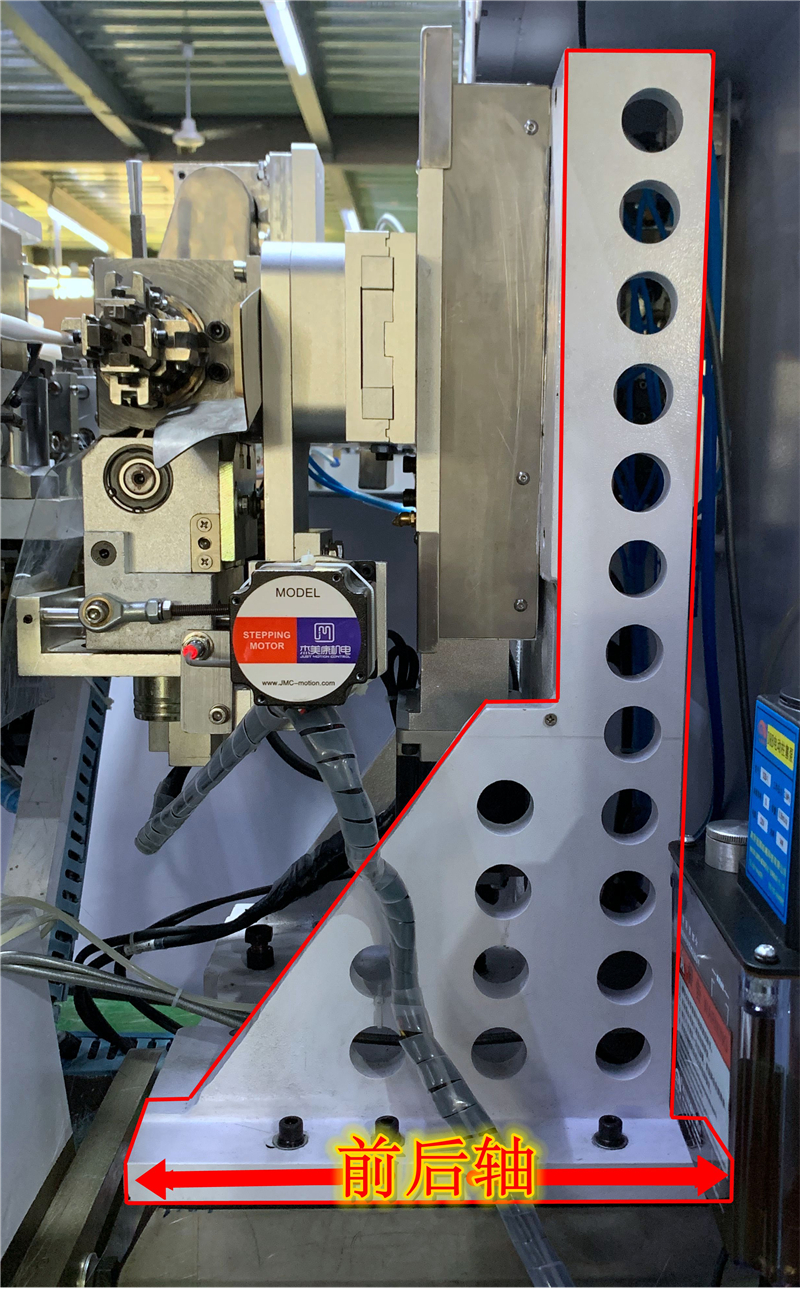

Karolo e Kobehileng

Sebopeho: 1. Ts'ebetso ea ho lahla, ho felisa khatello ea kelello e ka hare e bakoang ke ho sisinyeha ha thepa, e le ho netefatsa ho nepahala ha boemo bo pheta-phetoang.

2. Mochine oa mochine oa tafole ea ho sebetsa o entsoe ka har'a li-castings tse nang le sebōpeho sa L, tse utloahalang haholoanyane, e le hore matla a eona a jereng mojaro a be matla ho feta a mohoebi ea entsoeng ka ntle ho li-castings tse bōpehileng joaloka L.

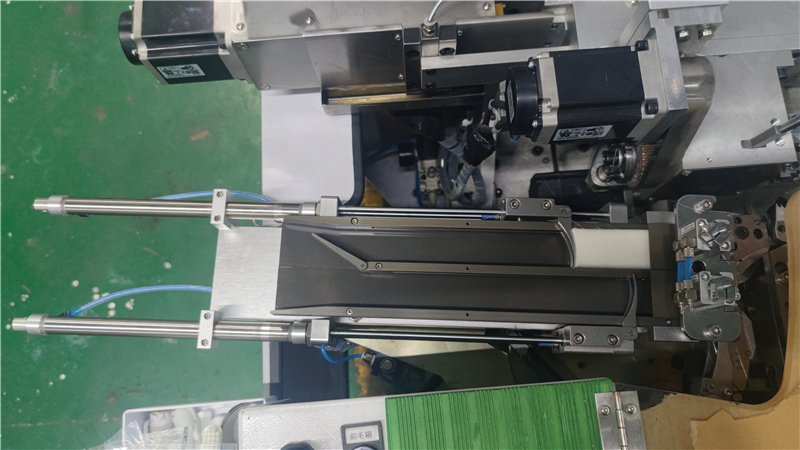

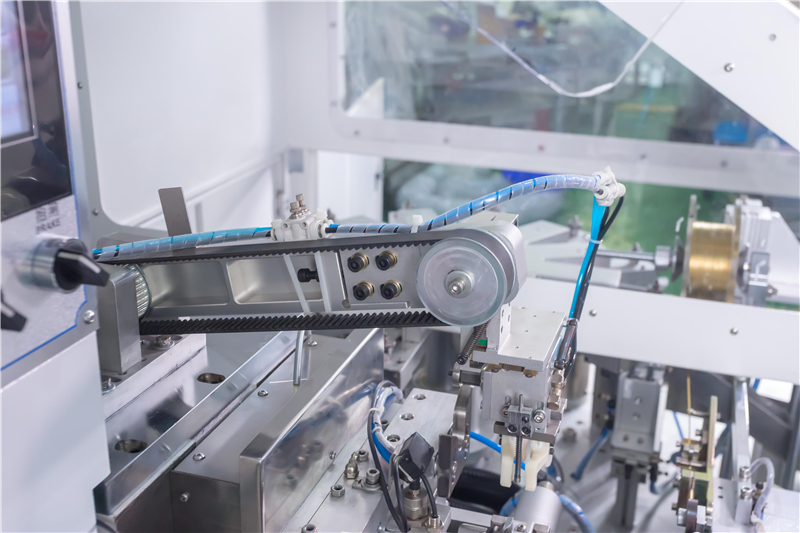

Manipulator: 1. Rocker Arm

Sebopeho: Moralo oa letsoho la rocker, 50% ka potlako ho feta lebelo le tloaelehileng la seporo sa tataiso, phetoho e potlakileng

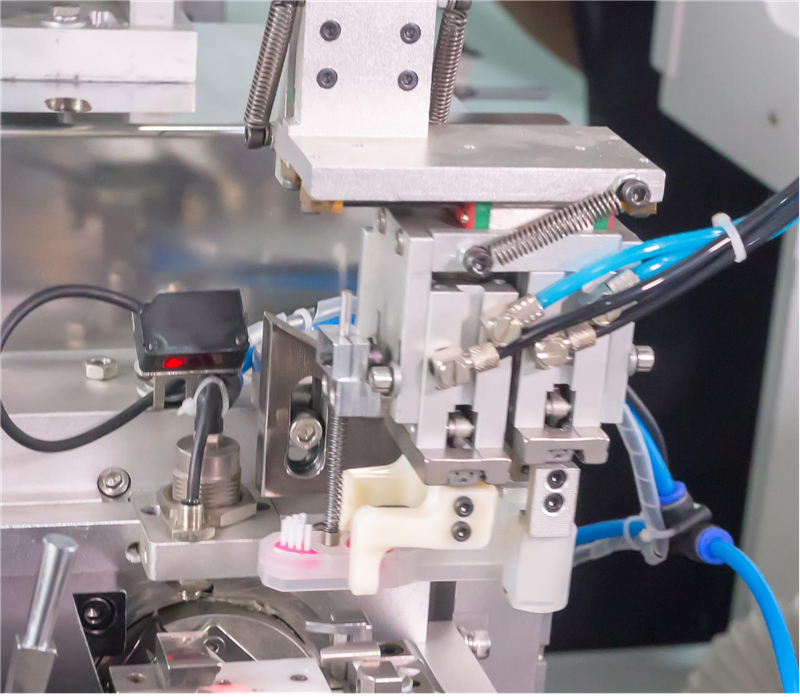

Manipulator: 2. Sekotwana sa Monoana

Tšobotsi: Hlooho ea borashe ba meno e etselitsoe ho tsitsa haholoanyane.Borashe ba meno bo nang le deformation e kholo ha ho bonolo ho koala sebapi ho eketsa tlhahiso.

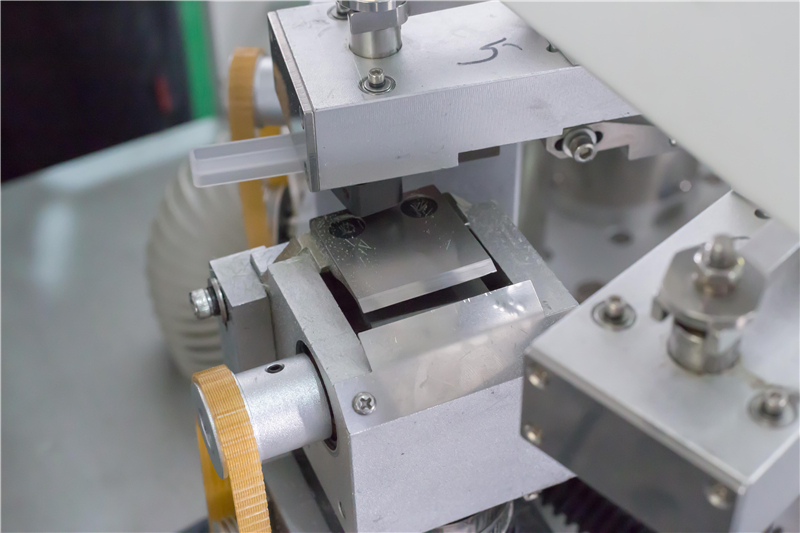

Ho sila: 1. Mechanical Connecting Arm

Sebopeho: Letsoho la mochini (ho hokahanya ho tloha ho tufiting ho ea ho sila) le boloka litšenyehelo tsa tlhahiso le ts'ebetso ea lisebelisoa, 'me ho bonolo ho fetola le ho nkela mochine sebaka.

Ho sila: 2.Sesebelisoa sa Nako

Feature: Moralo oa ho kuta habeli nakong ea ho sila, o loketse libopeho tse fapaneng tsa lihlahisoa tse etselitsoeng

Hlooho e Sila

Feature: sehlopha sa borobeli tsohle-directional positive le negative dimensional swing mofuta le imported daemane sila disc, e le hore karo-karolelano ea ho sila filament grinding round e phahametse 90% ho feta maemo a naha.

Sesebelisoa sa ho Tlosa Lerōle, Sesebelisoa sa ho Tlosa Lerōle

Sebopeho: Moralo oa othomathike oa sesebelisoa sa ho tlosa lerōle, sesebelisoa sa ho tlosa motlakase.

+86754-87916365

+86754-87916365

.png) 13342756672

13342756672